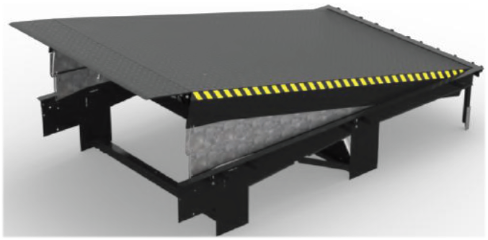

Dock Leveller – Loading Systems 232 Swing Lip

The Power Ramp 232 is an electro-hydraulic dock leveller including hinged swing lip is engineered and manufactured by leading European dock and door manufacturer Loading Systems International.

Advantages

Advantages of the The Dock Leveller 232

- Can be configured in a step-down arrangement for COLD CHAIN application, can operate in temperatures between -30 and +50 Celsius.

- Swing lip designs can be manufactured to the highest capacity of dock leveller design.

- Powder Coated Finish comes standard, Hot Dip Galvanised options also available.

- Deck plate manufactured from Durbar floor plate offering superior slip resistance and durability.

- Pit construction including hang or cast in place systems save construction and installation costs.

- Compatible with all BMP door products for easy integration with door packages.

- Interface with traffic lights, wheel chocks, vehicle restraint and protection systems.

- Capacity to suit even the heaviest and dirty applications.

- Heavy duty steel supports for transverse movements (cross traffic)

- Over 50 yrs. of engineering and manufacturing experience in proven design.

Capacity

Dynamic rollover capacity is the actual load that can be safely rolled across the dock leveller and into the rear of the trailer.

Two standard capacities are available across the Loading Systems range of dock equipment including 6KN and 10KN capacities offering a solution to suit almost any application. Heavier capacities can be designed and supplied, please contact your local HoldFast representative for further options.

Hydraulics

The platform deck as well as the lip are hydraulically actuated via a completely closed hydraulic system adding to the life of the hydraulics through reduction in maintenance issues from ingress of dust and contaminants in the harshest environments.

The over dimensioned, chrome hardened cylinders off the added advantage of a low working pressure of approximately 100 bars for superior longevity and reliability, all Loading Systems loading equipment is manufactured in accordance with EN 1398 European standards, CE Mark.

Power & Protection

3 Phase, 415VAC, 50 Hertz, 24VDC Control, IP 65

Compliance

EN1398

Operation

A single press of the “dock raise” button raises the deck to full height; the lip will automatically swing out from the vertical position to the horizontal.

By releasing the push button, the deck will automatically lower down onto the vehicle floor.

Upon completion of loading/unloading, the “dock raise” button is pressed once again, as the deck raises up the lip automatically swings back to the vertical position for stowing back in the cross-traffic position.

Structure

The 232 offers a 490mm long self-cleaning open lip swing hinge construction made of high-quality durbar plate, superior smooth transition, great slip resistance, durability & high capacity.

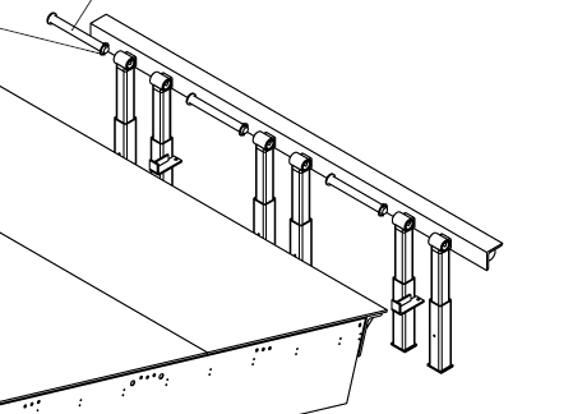

The rear hinge assembly of the deck is connected to the lower frame by means of three hinges

strengthened along the 232 leveller’s length by means of 10-12 set profiles.

The dock leveller deck can “twist” and compensate for vehicle “tilt” caused by set loads of the vehicle bed up to a 100mm from the horizontal, 25mm drawn steel pins are used for the lip hinge at the front of the platform top for a robust design and long-life span.

The self-cleaning, open lip hinge construction helping to extend life and reduce maintenance costs of the dock leveller.

In the cross-traffic position, the 233 has been designed with a robust front channel for absorbing the forces created by an emergency stop and where end loads are being loaded below dock height.

Dock Leveller – Loading Systems 232 Swing Lip

Would you like to know about finding the best solution for your application?

Then contact our friendly and experienced team for advice on the ideal product for your needs.

CONTACT US

Need help from our specialists?

Let’s discuss the best solution for you. Use the form below or don’t hesitate to give us a call on 1800 453 378.